News

News Contact Us

Contact UsContacts: Mr. Liu

Mobile phone: 0086-15935030555

Landline: 0086-350-6072118

Fax: 0086-350-6072068

Email: 373839228@qq.com

Post Code: 035400

Address: Zhuangli Industry Zone,

Dingxiang,Xinzhou, Shanxi, China

Website: www.xsflange.com

Use of plastic flange mirror

Use of plastic flange mirror:

Plastic mirror is industrial plumbing fixtures on one of the main accessories, in the pipeline in the petroleum, chemical, pharmaceutical, food and other industrial production device, PP mirror or PVC as the cup ready to observe the pipeline liquid, gas, steam and other media flow and reaction, to monitor production, obstacle free production in the process of the accident.

Plastic valves and piping systems are connected to the way

Welded connections: valve connected parts and the outside diameter of the pipe is equal to the outer diameter of and valve connected parts and the end surface of the pipe end relative to welding.

Jack bond connection: valve socket joints to form, bond with the pipe fittings to connect;

Fused socket connection: connect the valve parts for the diameter of the laying of electric wire socket, fused with the pipe connection;

The connecting part of the connecting part of the valve is the form of the connecting part of the valve, and the pipe is connected with the pipe;

The connection between the bearing and the mouth is the connecting part of the valve, which is in the form of the connecting part of the valve;

Connection of the sealing ring of the bearing ring: the connecting part of the valve is the socket type of the inner rubber sealing ring, and the connecting part of the valve is connected with the pipe;

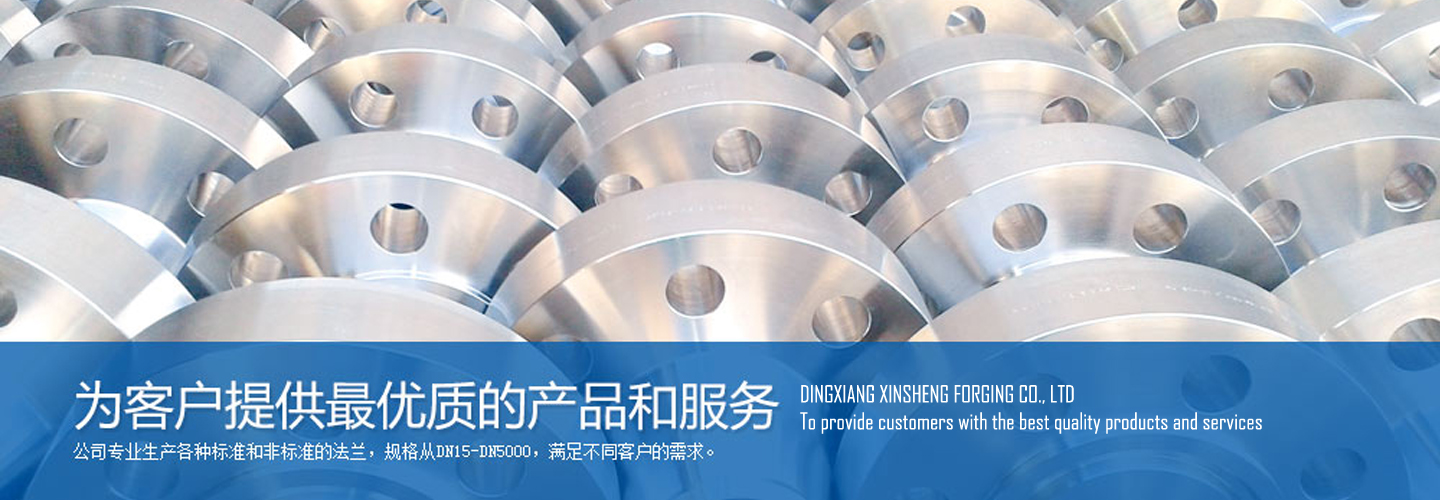

Flange connection: valve connecting parts for the flange form, and the pipe flange connection;

Thread connection: the valve connecting part is the thread form, and the thread is connected with the pipe or pipe fitting;

Live connection: the valve connecting parts for the living form, and pipe or pipe connection.

A valve can also have a different connection mode.

Relationship between pressure and temperature

With the increase in temperature, the use of plastic valves to shorten the service life. To maintain the same service life, it is necessary to reduce the use of pressure.